Crisis Management and Product Recall

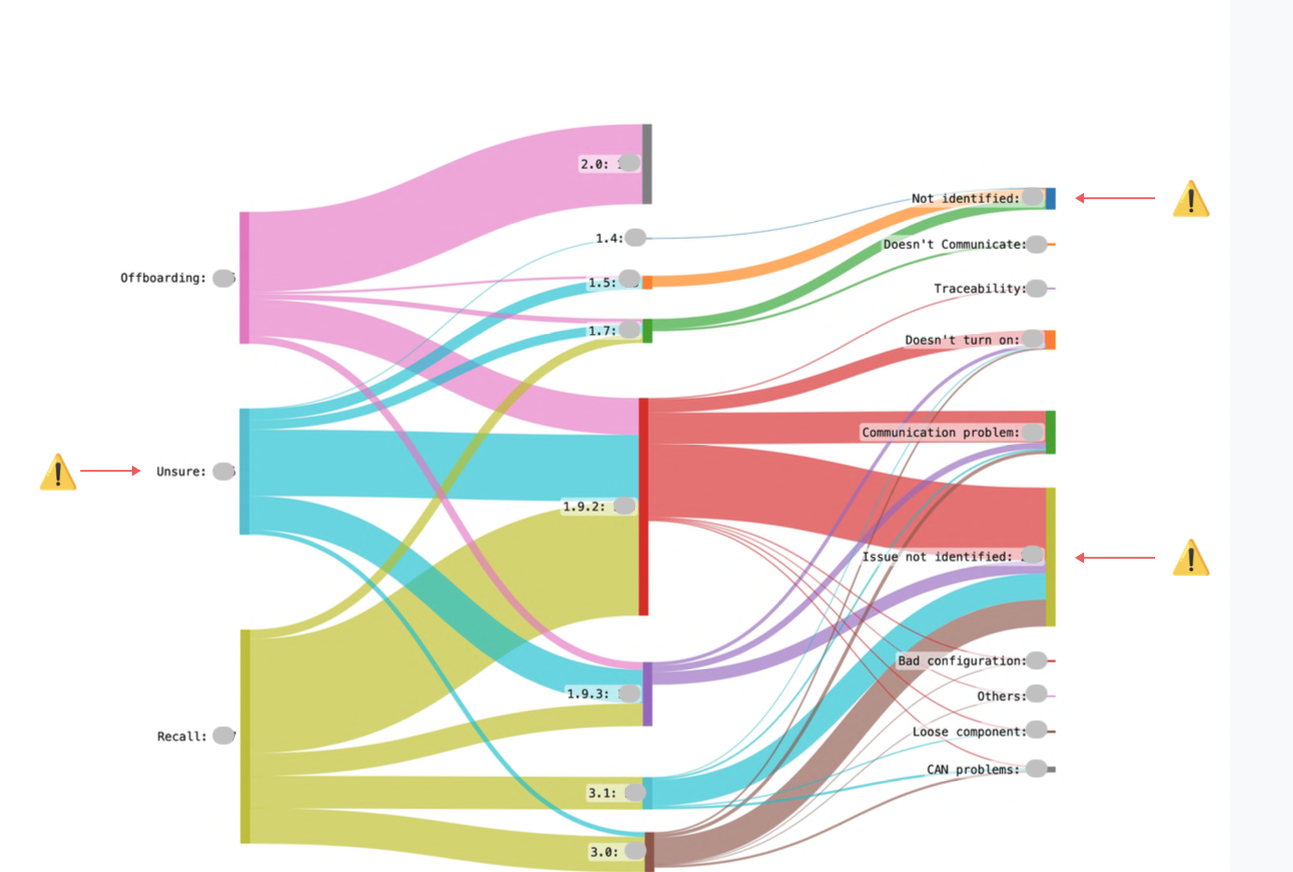

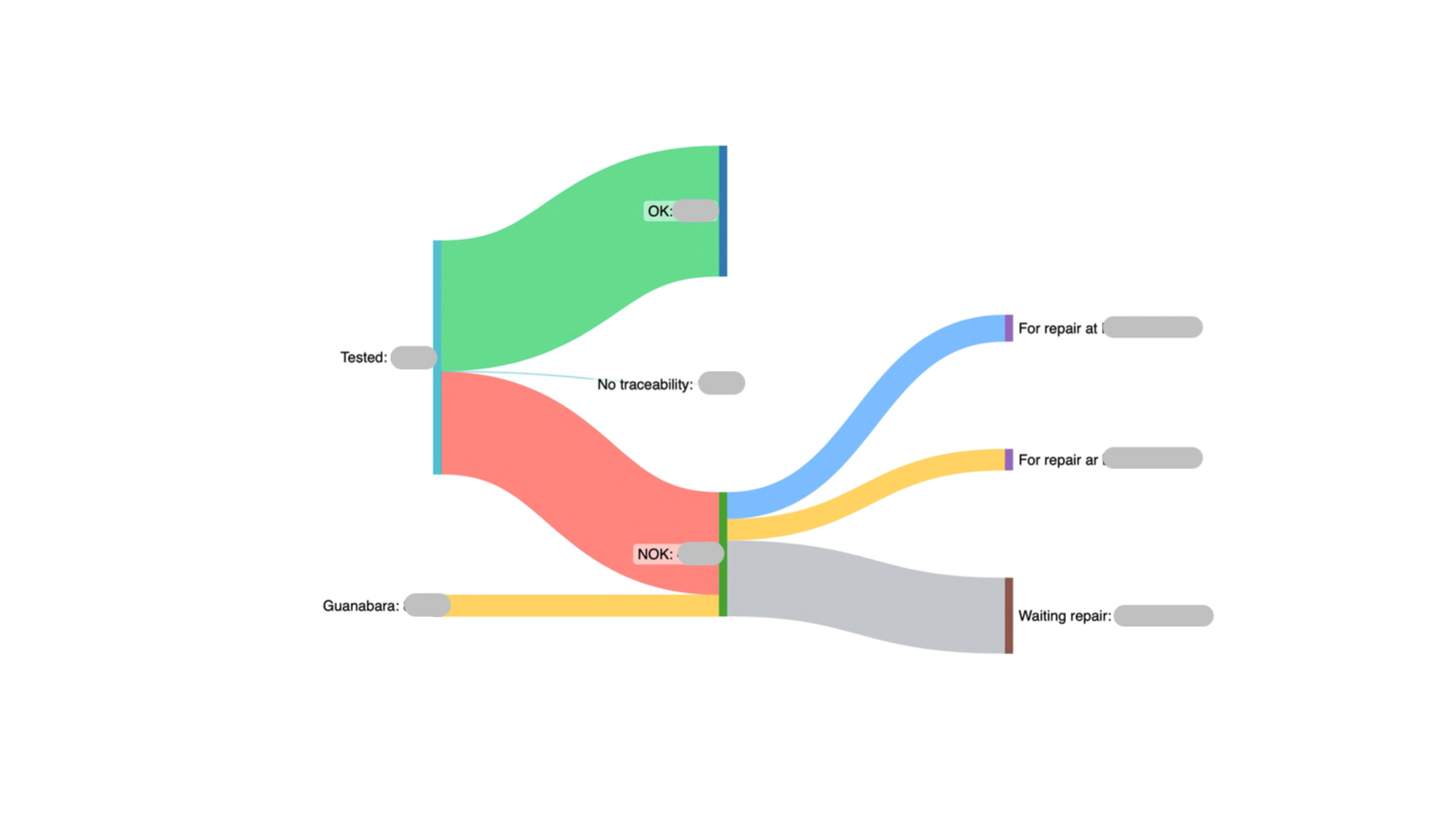

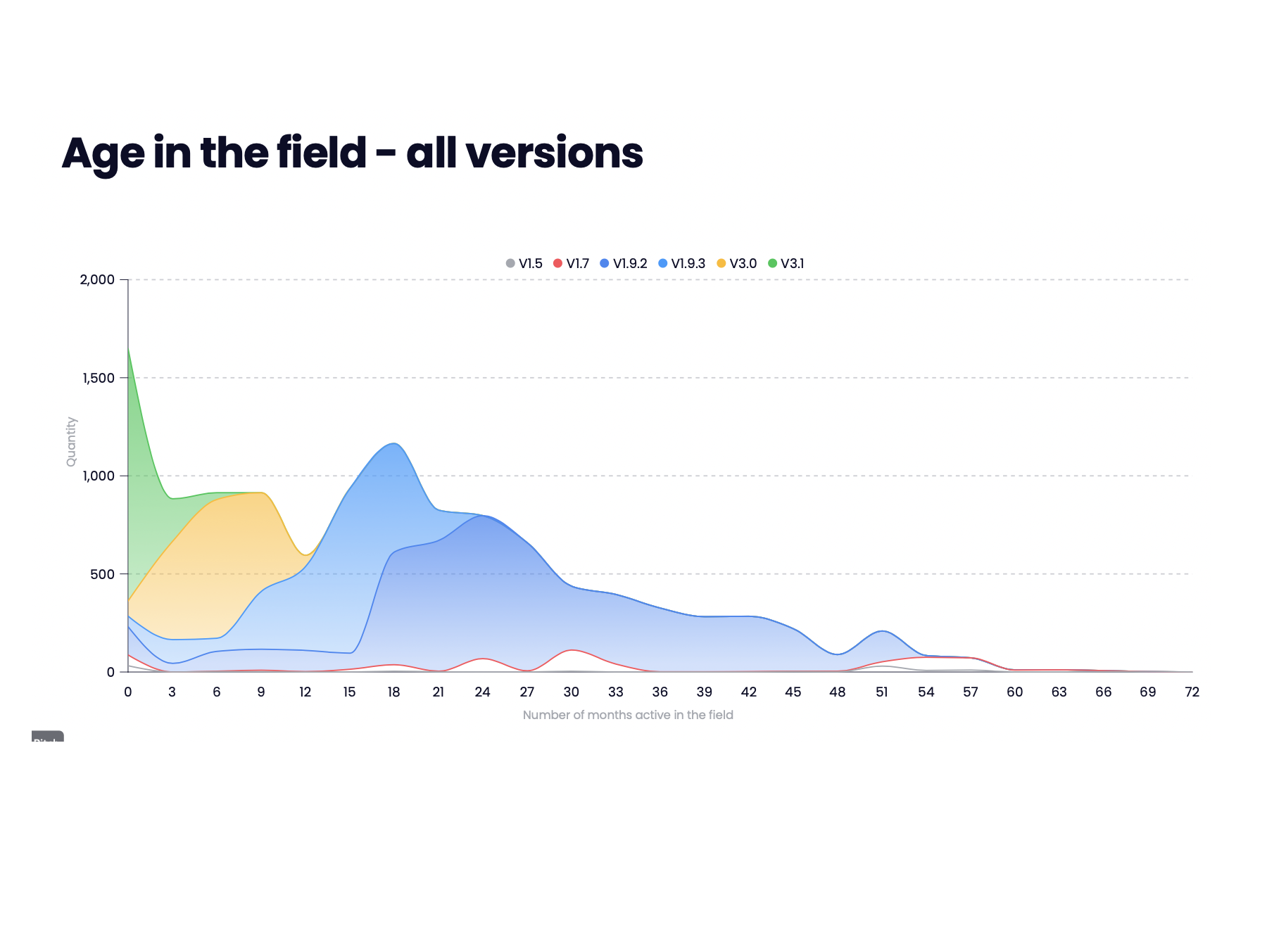

Led a critical recall project for a faulty manufacturing batch, coordinating cross-functional teams and maintaining stakeholder communication. Worked with the hardware team and the Contract Manufacturer to identify the defective batch, pinpointed the issue's origin, designed and developed test jigs in record time, and managed testing, tracking, and rework instructions for local and offshore contract manufacturers. Delivered a comprehensive resolution that minimized downtime and established processes to prevent similar issues on future manufacturing cycles.

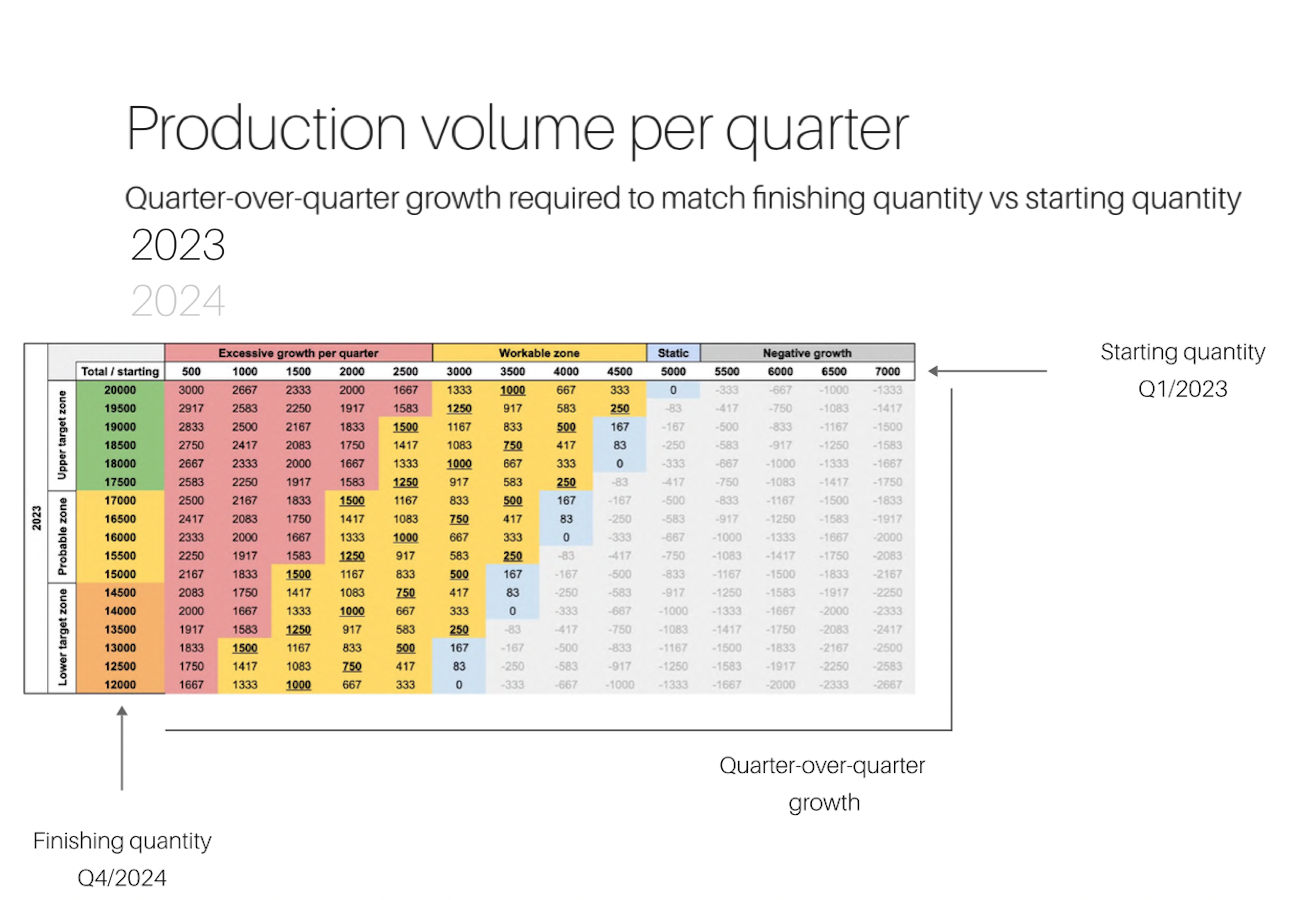

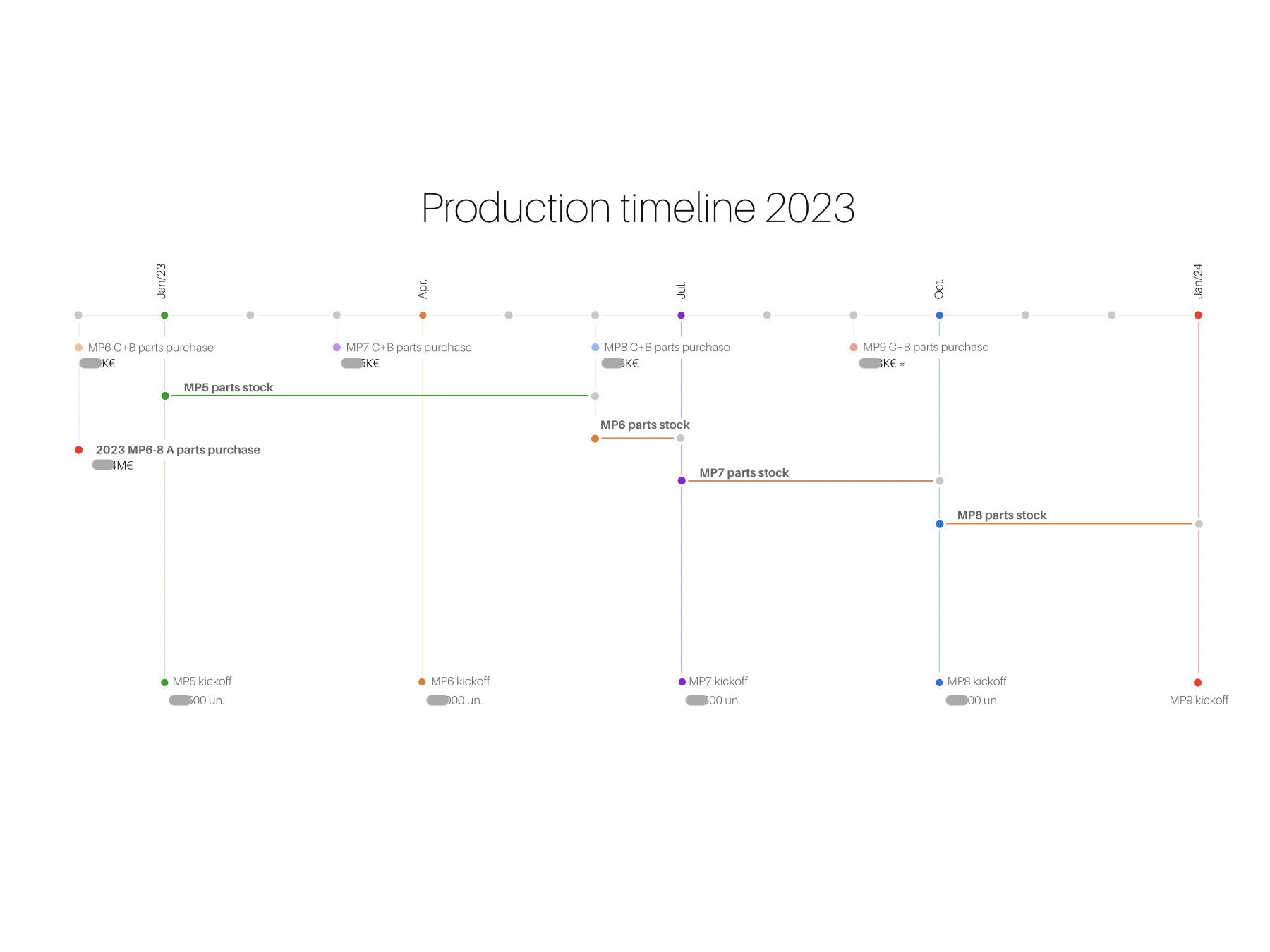

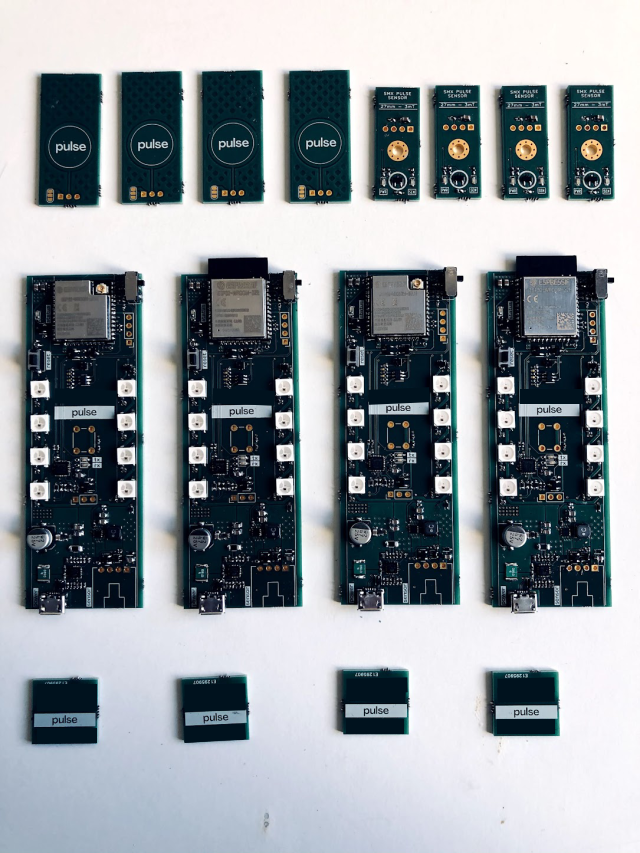

Scaling Manufacturing and Industrialization

Directed the industrialization and manufacturing ramp-up for a 10,000-unit production run, resolving supply chain challenges and ensuring tight operational oversight. Established robust processes for contract manufacturing, incoming quality checks, and inbound logistics, driving operational efficiency and production reliability under tight deadlines.

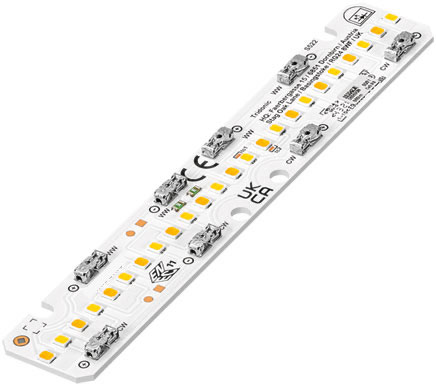

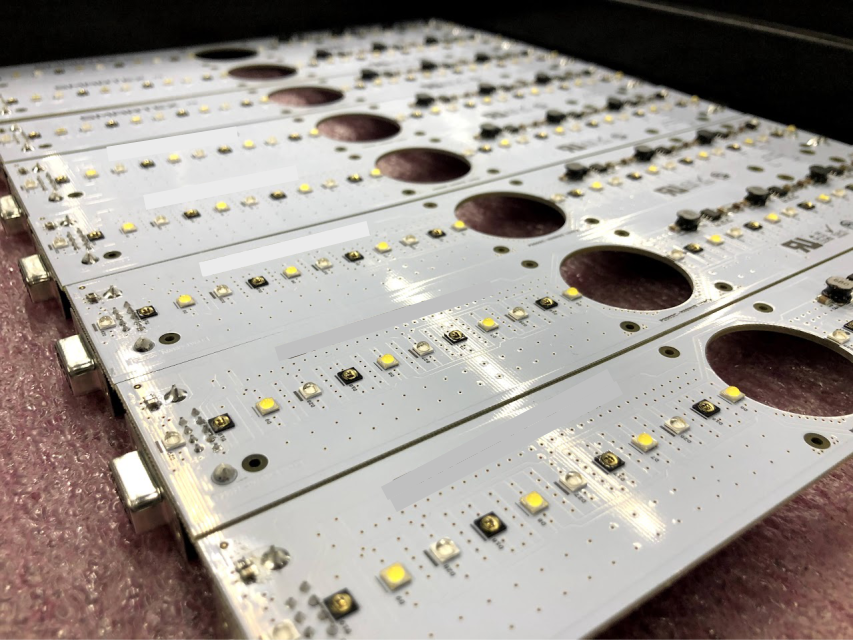

LED lighting

Designed high and mid-power LED lighting solutions for residential and commercial buildings across 100+ projects. Delivered rapid turnaround designs with several iterative improvements, optimizing for performance and reliability.

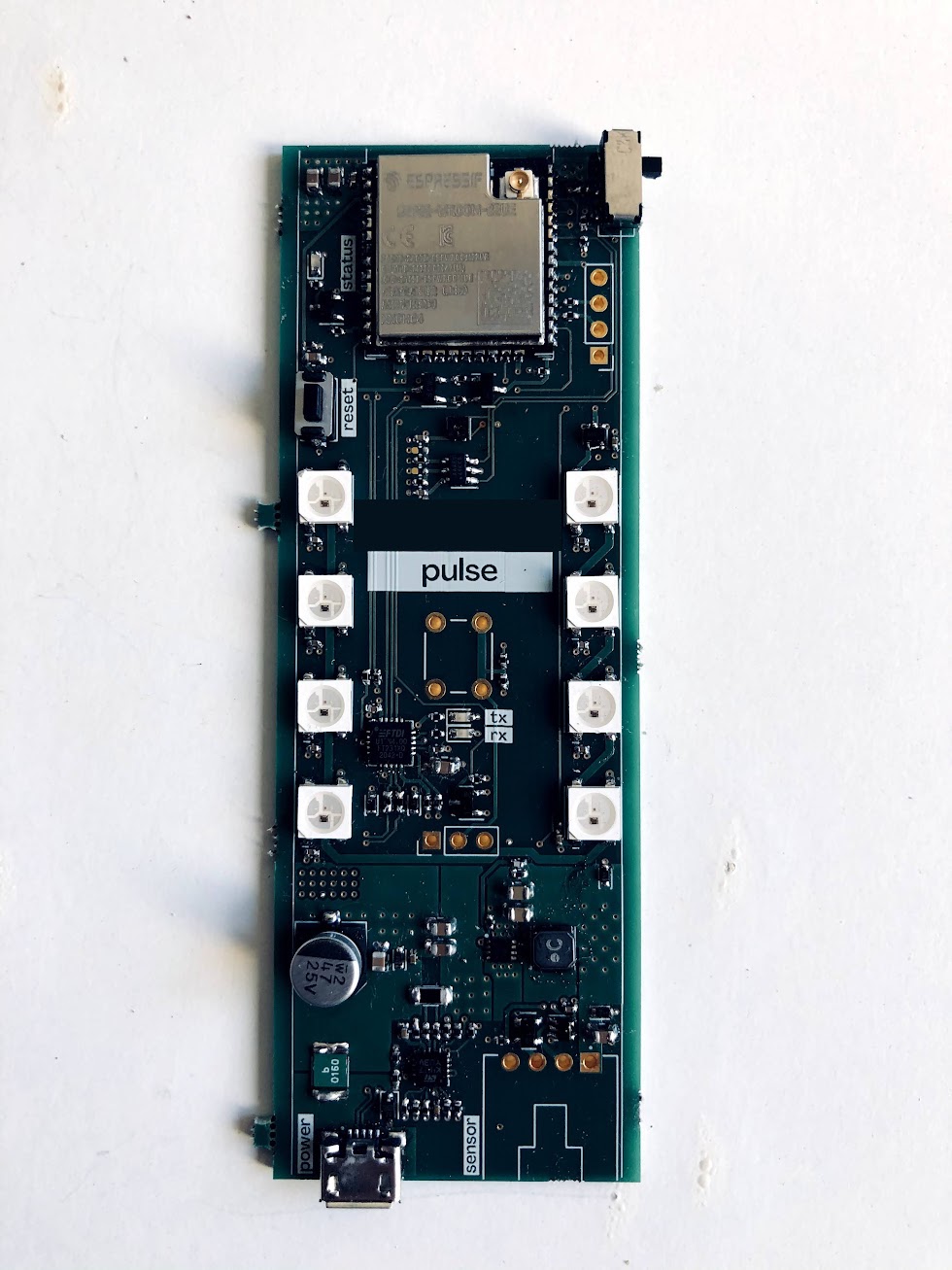

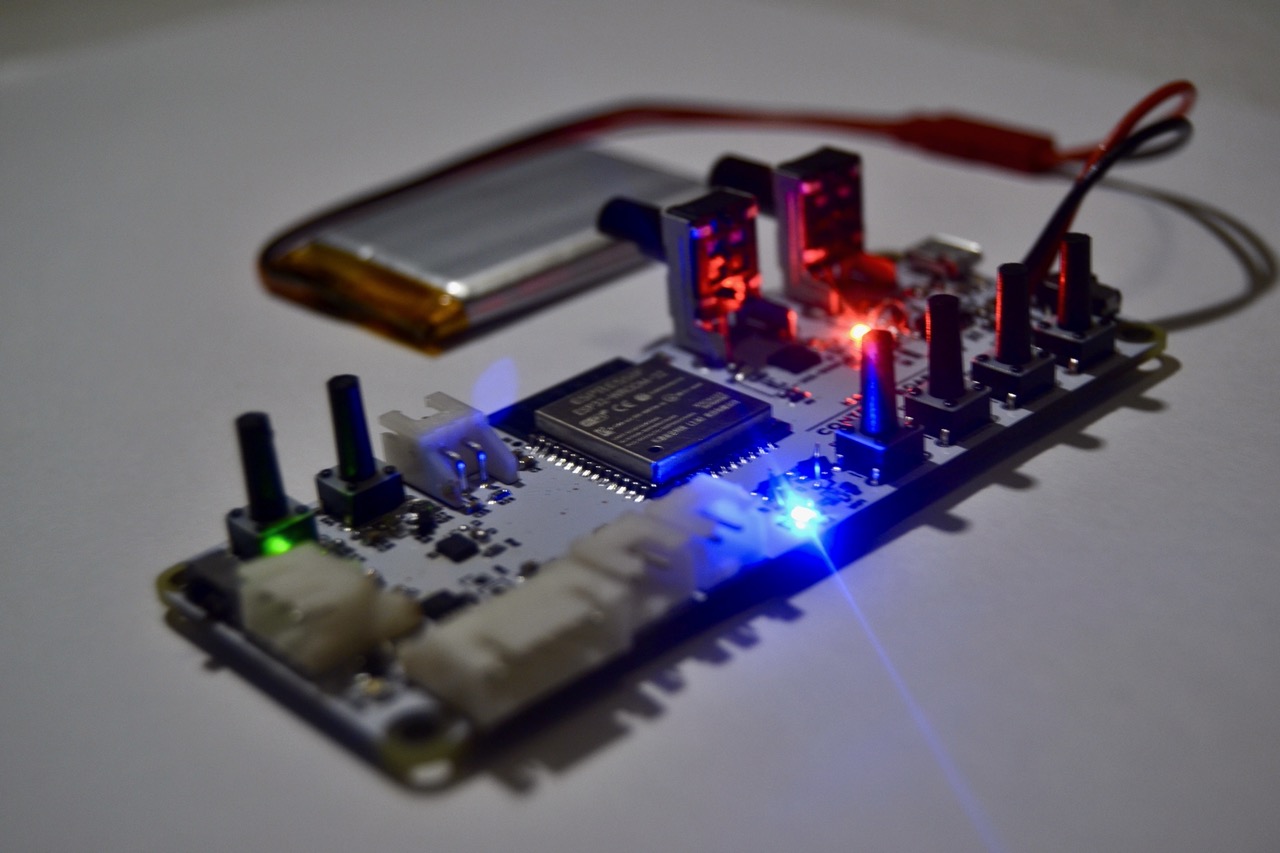

Industrial Machinery Monitoring System

Developed an industrial machinery monitoring system, progressing from proof-of-concept to field tests. Retrofitted legacy equipment with WiFi-enabled ESP32 for connectivity, Hall-effect sensors for RPM monitoring, and RGB LEDs for user feedback. Delivered real-time data reporting for improved equipment uptime and performance analytics.

IoT Quality Control System

Designed and scaled and IoT quality control system from proof-of-Concept through mass production. The system incorporated a single-board computer, multiple USB cameras, and a multi-spectral lighting system. The device monitored machine speed though a gyroscope and triggered the capture of images on the cameras while providing adequate lighting. Device was designed to be retrofitted into exisiting industrial machines.

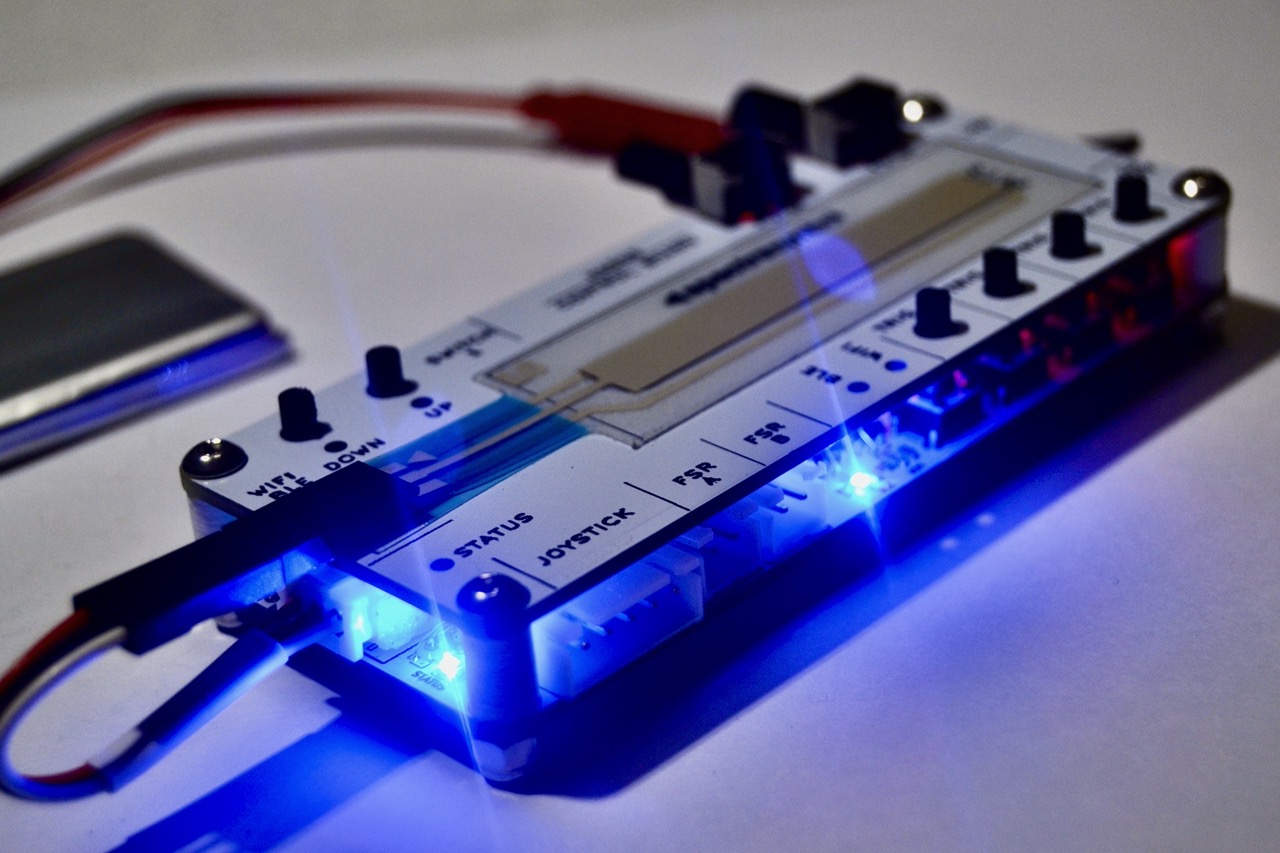

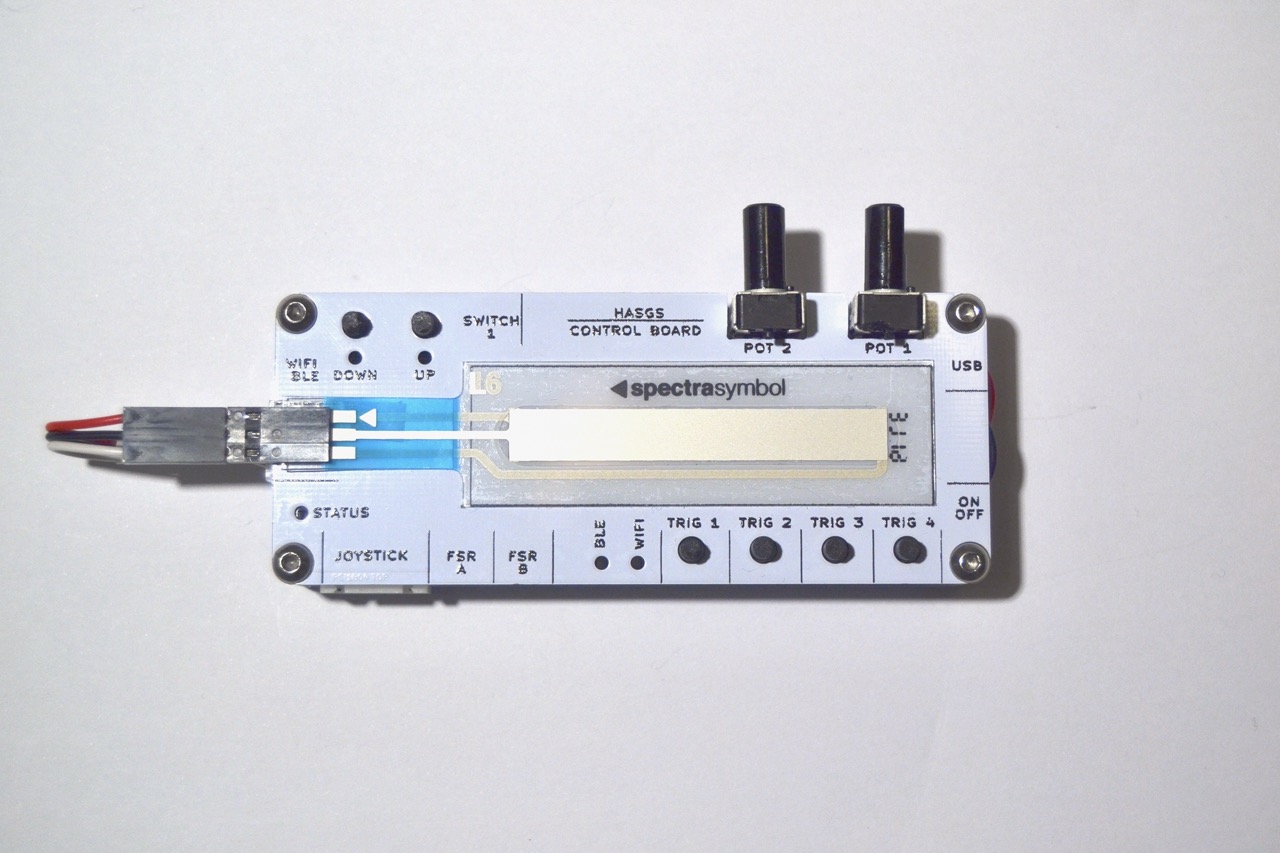

Wireless MIDI controller

Designed a wireless MIDI controller for seamless integration with musical instruments, enabling real-time video and audio effects. Engineered WiFi/Bluetooth connectivity, analog sensors, LiPo battery management, and IMU-based gesture sensing, creating an intuitive performance tool for live events.

+ Info: HASGS: 5 Years of Rediced Augmented Evolution / Henrique Portovedo / HASGS / Composition Models for Augmented Instruments

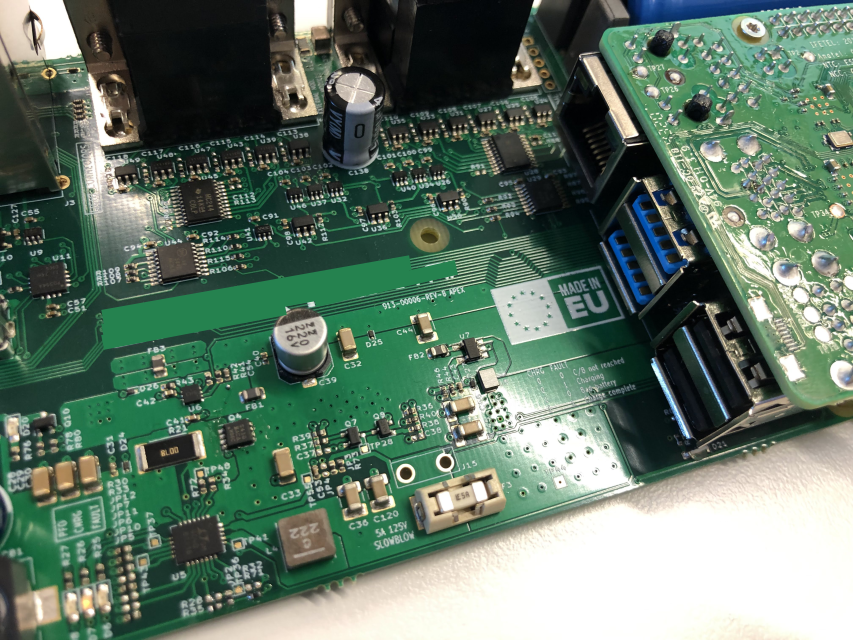

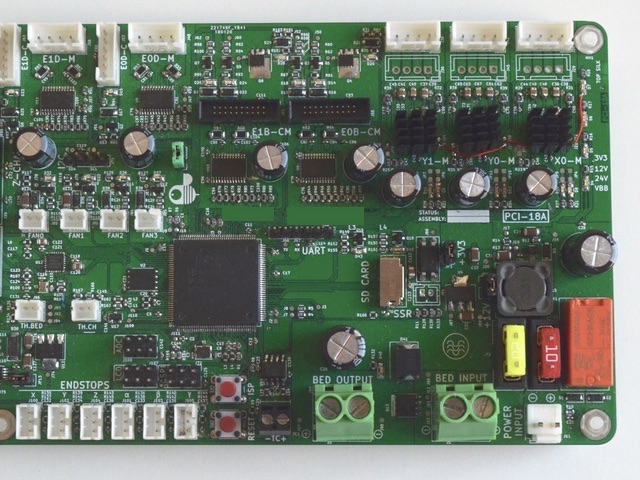

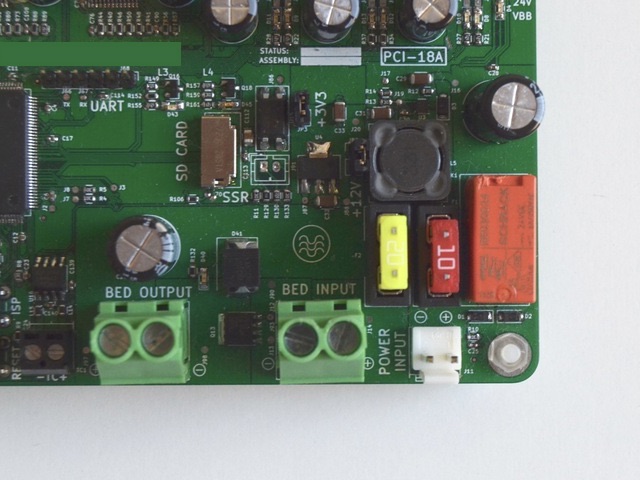

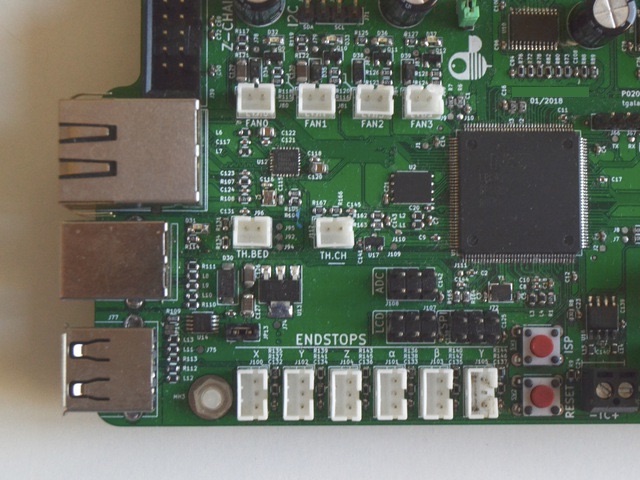

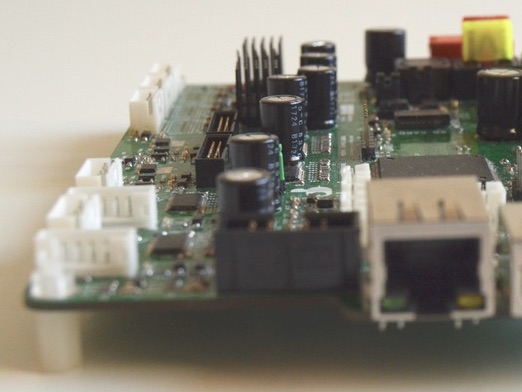

3D Printer Control Board

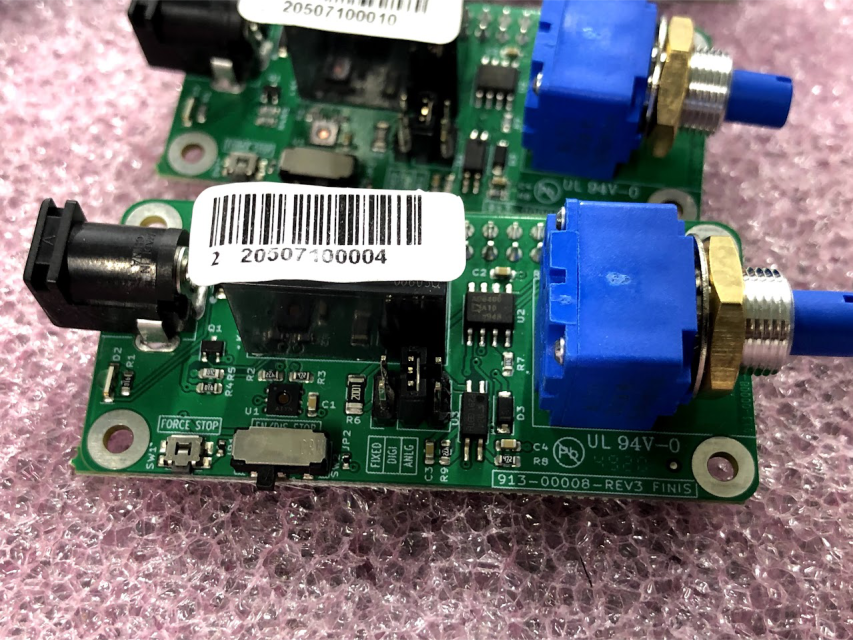

Developed an advanced 3D printer control board integrating high-end stepper motor controllers, a 32-bit NXP iMX processor, and dual-axis motor control. Supported SD-Card/USB file systems, Ethernet connectivity, multiple extruders, and thermocouple interfaces for high-precision printing.

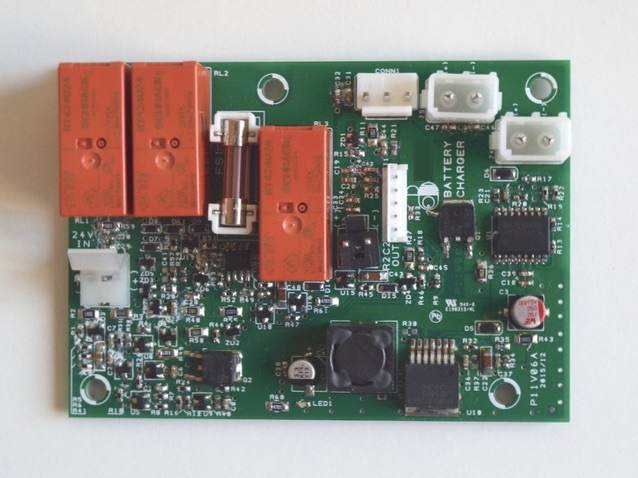

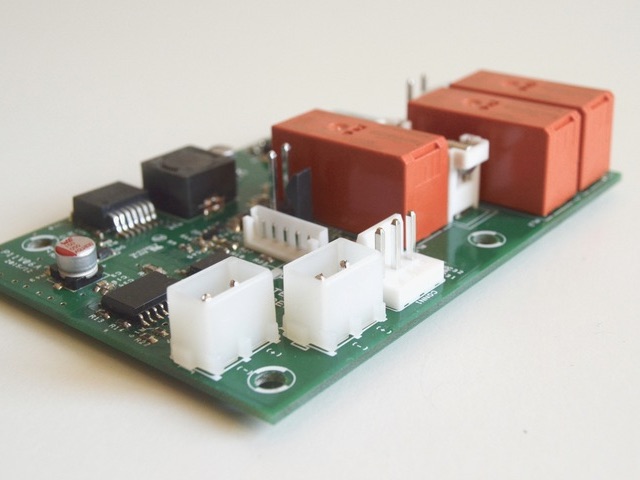

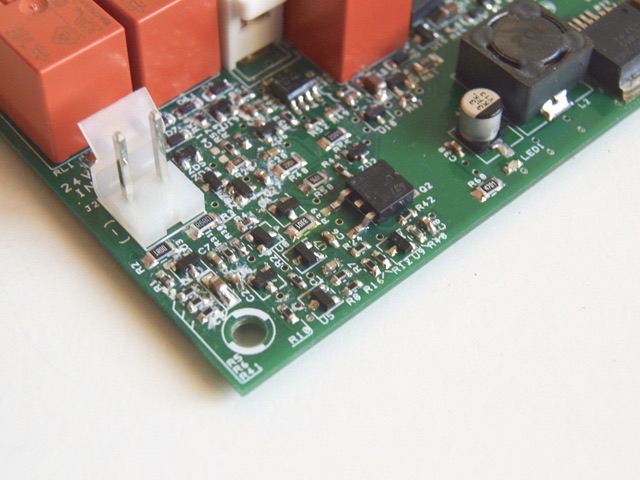

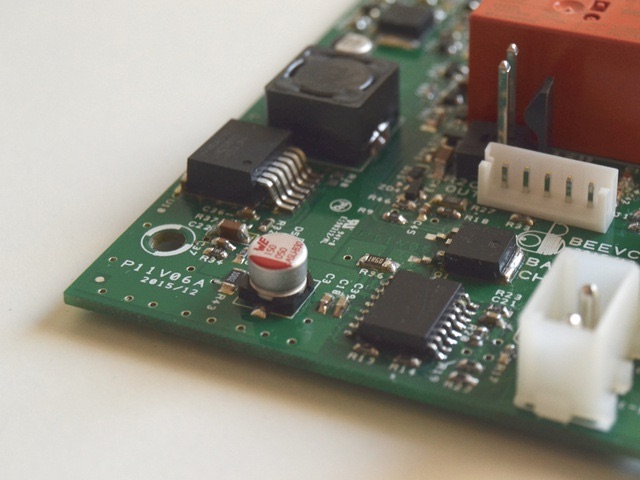

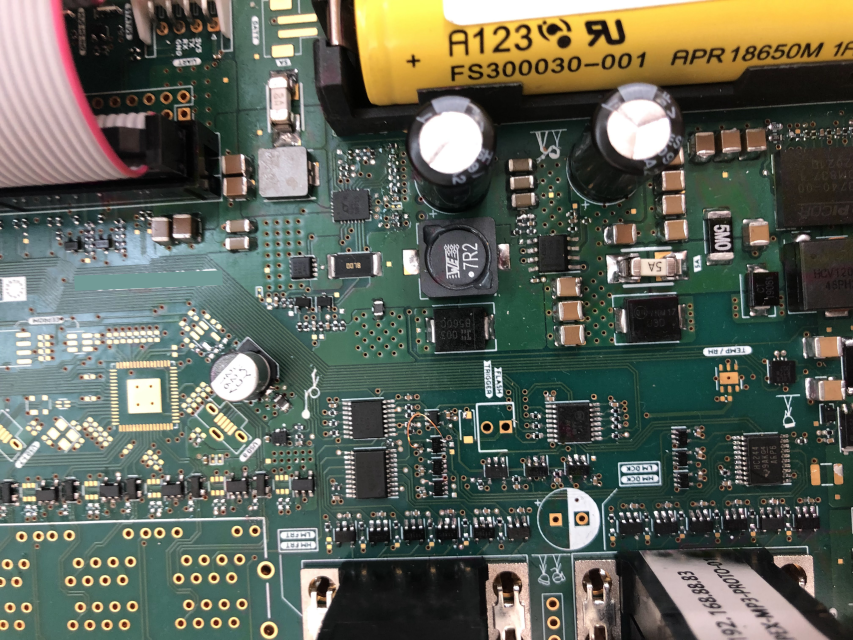

Lead-acid Battery Management System

Designed a lead-acid battery management system for 3D printers, incorporating polarity inversion and over-current protection for dual 12V cells. Delivered proof-of-concept prototypes, longevity testing, and compliance for reliable power management.